Casthouse - Foundry Management & Operation

Quickly get started improving your operational efficiency and quality with MES-AL. Manufacturing Execution System Aluminium is built on years of operational experience in the aluminium industry around the world.

MES-AL delivers information enabling the optimization of production activities from order registration to finished goods.

Learn more

Manufacturing Execution System Aluminium

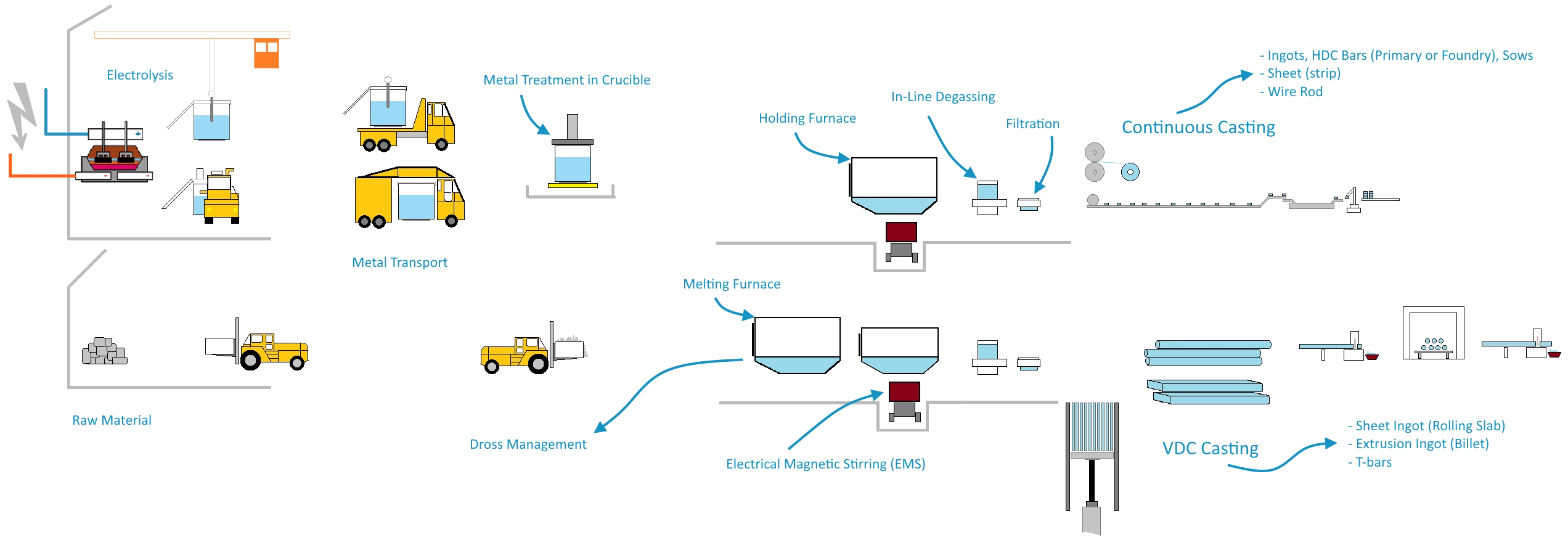

MES-AL casthouse and foundry management software solution is built on years of operational experience in the aluminium industry. Casthouse and foundry operation is frequently operated as a group of autonomous processes with limited or no communication between them. MES-AL provides mission-critical information about production activities across the enterprise and supply chain via bi-directional communications. Providing management and operators with correct information at right time.

As industries are moving towards the Forth Industrial Revolution, sometimes referred to as Industry 4.0 the need for dedicated manufacturing execution system like MES-AL is growing. MES-AL supports connection to ERP systems and cloud-based solution as well as locally based.

Production & Customer Alloys

All production is based on productions alloys that are derived from customer alloy specifications. Chemical composition deviations within customer specification are highlighted for each batch and product. When product is ready CoA (Certificate of Analysis) according to EN-10204 is automatically generated.

Raw Material Optimisation & Sustainability

Focus on sustainability requires optimising the use of worst-case scenario raw materials to keep high recycling ratio and minimising the usages of expensive alloying material. At the same time, the process must deliver quality products. MES-AL has the capability to support this process, raw- and alloying material consumption is registered, and unwanted actions are identified and avoided. These actions improve quality and lower the operational cost.

Batching & Standardised Work

Work orders are loaded per furnace, batching cycle time is based on predefined standardised work for alloy-product. Detailed information for each process step is included. Graphical overview of actual chemical composition, internal and external composition limits and alloying targets.

Digitized Manufacturing Processes

When integrated with quality management and process control, changes to specifications, recipes or standardised work procedures are automatically communicated through a paperless system. There are no “old” paper copies that can result in a safety hazard, lost time, or waste. There is a full system traceability, as all actions and changes are logged in the MES-AL system.

Facts About MES-AL

Al-Genius

Process Know How & Support

In addition to the MES-AL system, Al-Genius provides consulting services to the aluminium industry. Core focus is on value added production, project management, continuous improvement, supply chain management and use of industrial data to support management decisions.

Projects worked on include the entire spectrum of products, sheet ingots, extrusion ingots (billets), and foundry alloys. As well the whole project lifecycle from feasibility studies, design, equipment selection, installation, operational readiness, commissioning, and operation.

Al-Genius mission is to help our customers in improving their performance and their production. If you are interested in exploring our capabilities, please fill out the contact form and let’s find out how we can help you improve your business.

Contact Form

Fill out the form to find out more about Al-Genius and the MES-AL system, or to schedule your online MES-AL demo.